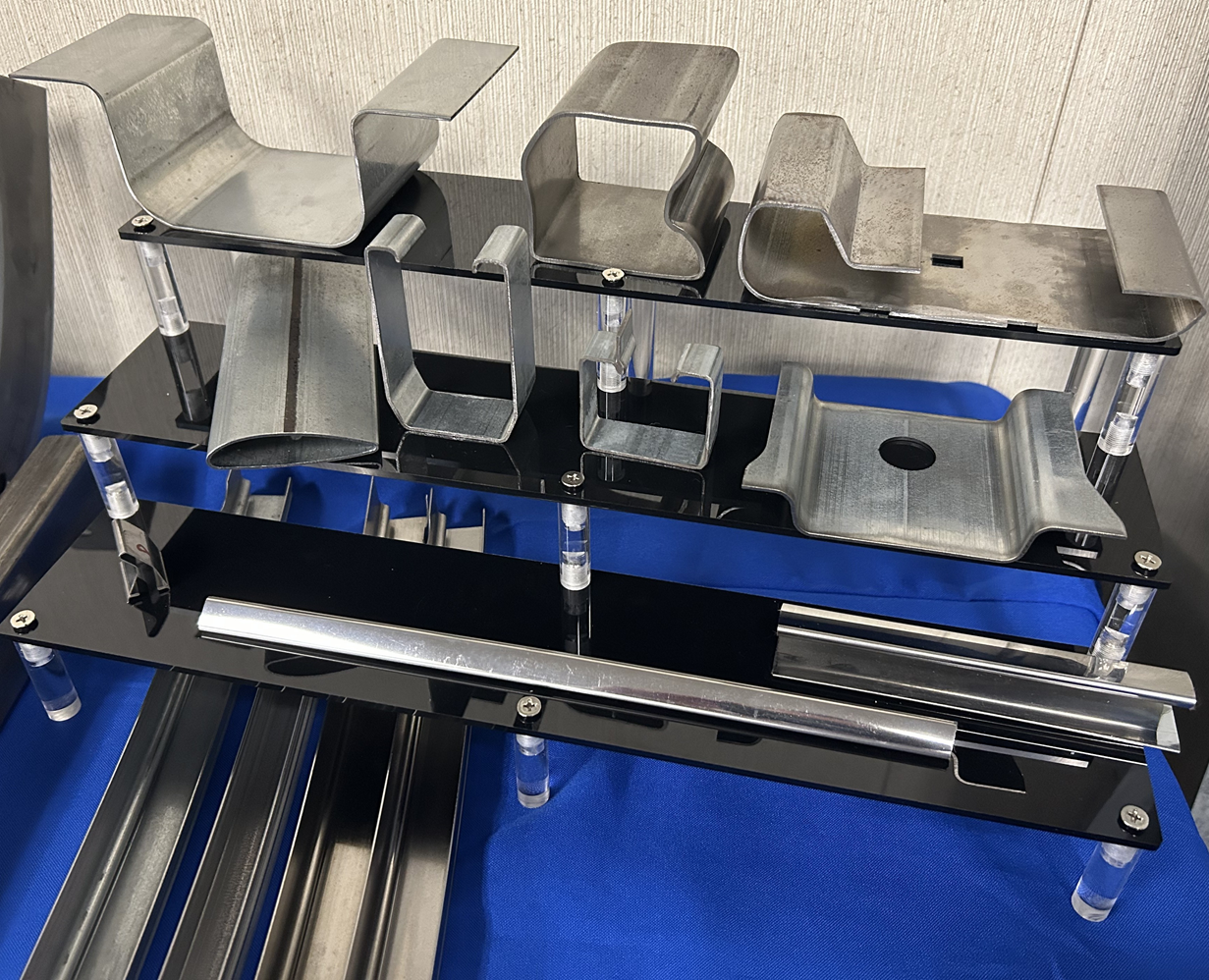

Custom roll forms and secondary tooling are designed and fabricated in-house to meet your needs and machinery specifications.

D&N Bending can restore worn or damaged rolls, and can turn rolls with CNC or manual lathes. Our tool rooms manufacture sweep blocks, straighteners, and section gages.

D&N Bending currently has 22 roll mill lines and can produce sections up to 60” wide.

At D&N Bending, our secondary operations enhance part functionality and precision, including:

Roll Forming: Precision and Efficiency for Long, Consistent Profiles

Roll forming is a continuous bending process that transforms long strips of sheet metal into precise, desired cross-sections. This is achieved as the strip progressively passes through a series of roller sets, each incrementally shaping the metal until the final profile is formed. This method is exceptionally well-suited for producing high volumes of long parts with consistent cross-sections.

Integrated Punching and Cutting Capabilities:

Our roll forming lines are highly configurable to integrate punching and cutting operations, enabling continuous production.

Some roll forming lines may incorporate a single punching or cutoff application, while others integrate multiple or all of these applications into one streamlined line.

D&N Bending is committed to securing our future in the marketplace by supplying world class, quality products that exceed our customer’s expectations.

We’re always interested in new projects, big or small. Please don’t hesitate to get in touch with us regarding your project.

Contact our main line with any questions or concern

Send us an e-mailWould like to submit a proposal for consideration simply

Request A Quote© 2017 D&N Bending. Developed by 24X7WP Support